As one of the top China cardboard tube packaging manufacturers and paper tube packaging suppliers, we devote all of our efforts to research and launch more high quality packaging products to global market.

While often used interchangeably in everyday language, the terms "cardboard" and "corrugated" refer to distinct, yet related, materials crucial to the packaging industry. Understanding this distinction, along with the different forms and manufacturing processes, is fundamental to appreciating the versatility and impact of this ubiquitous material.

1.Cardboard vs. Corrugated: Clarifying the Terms

At its most basic, cardboard is a general term that encompasses a range of thick, paper-based materials. Think of it as a broad category for paper products thicker than standard writing paper. It can be a single layer, relatively rigid sheet, or multiple layers pressed together.

Corrugated fiberboard, often what people actually mean when they say "cardboard box," is a specific and highly engineered type of cardboard. Its defining characteristic is its structure: a fluted (wavy) layer of paper, known as the "medium" or "fluting," sandwiched between two flat layers of paper, called "liners." This innovative design, inspired by the structural strength of arches, creates a series of air columns that provide exceptional rigidity, cushioning, and insulation, making it ideal for shipping and protecting goods.

Types of Cardboard: A Spectrum of Applications

Beyond the core distinction, various types of cardboard are tailored for specific packaging needs:

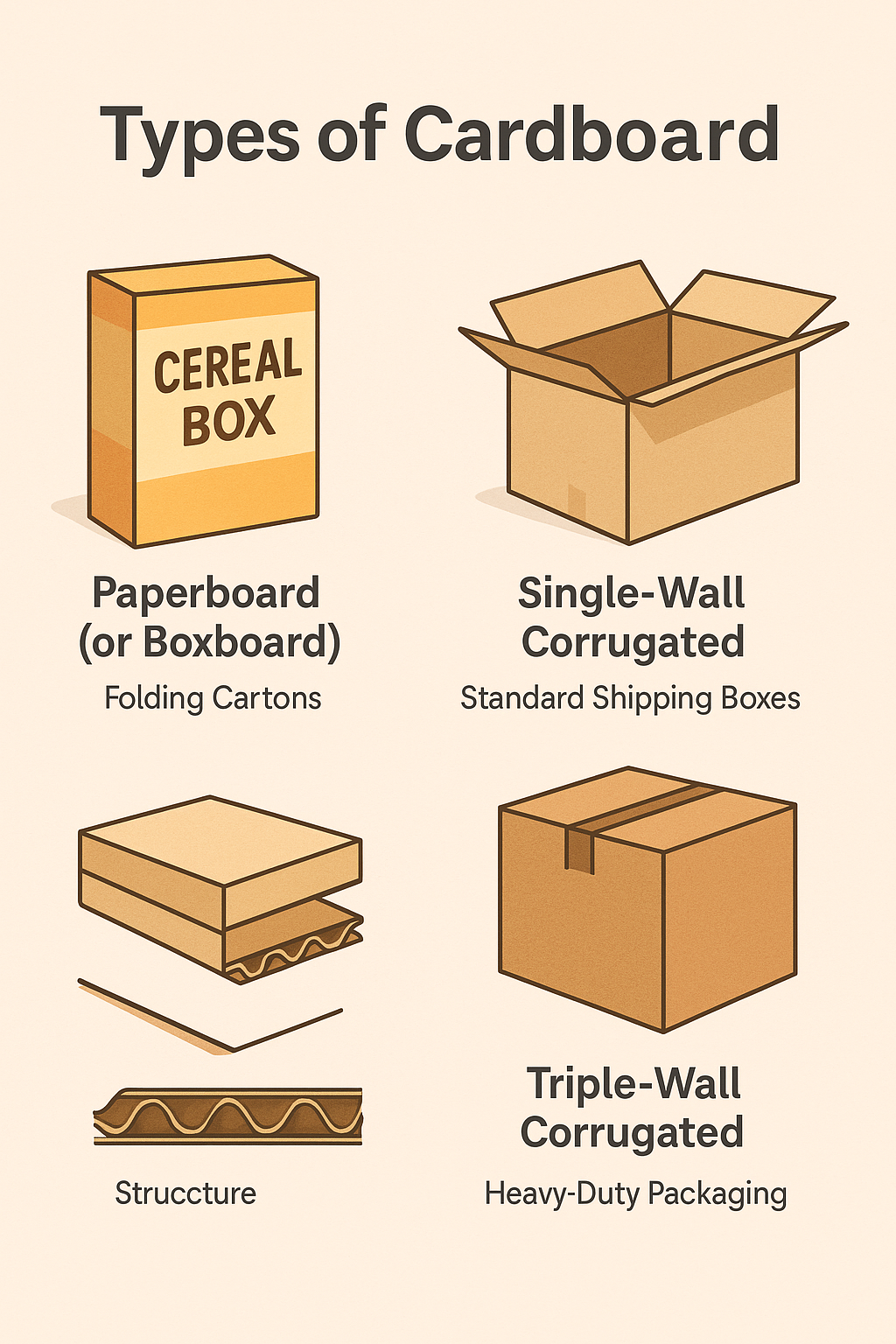

Paperboard (or Boxboard): This is a thinner, often single-ply cardboard used for folding cartons. Think cereal boxes, tissue boxes, or retail product packaging for items like medicines or cosmetics. It's easily cut, creased, and printed, making it perfect for consumer-facing packaging where aesthetics and brand messaging are key. It can range from lightweight chipboard to higher-quality solid bleached sulfate (SBS) or coated unbleached kraft (CUK).

Corrugated Fiberboard: As detailed above, this is the workhorse of shipping and protective packaging. Its strength comes from its multi-layered structure. The most common types include:

Single-Wall Corrugated: Consists of one fluted layer between two liners. This is the most common type for standard shipping boxes.

Double-Wall Corrugated: Features two fluted layers and three liners, offering increased strength and protection for heavier or more fragile items.

Triple-Wall Corrugated: Composed of three fluted layers and four liners, providing maximum strength for very heavy or delicate industrial goods, often replacing wooden crates.

The size and shape of the flutes (A, B, C, E, F) also vary, influencing crush strength, printability, and cushioning properties, allowing for further customization based on the product being protected.

From Pulp to Parcel: The Manufacturing Process

The creation of cardboard, whether paperboard or corrugated, begins with raw materials – primarily wood pulp and/or recycled paper fibers. The process can be simplified into a few key stages:

Pulping: Wood chips or recycled paper are mixed with water and chemicals to break down the fibers into a pulpy slurry.

Papermaking: This pulp is then spread onto a large mesh screen, where water drains away, leaving a moist fiber mat. This mat is pressed, dried, and sometimes calendered (smoothed between rollers) to form large rolls of paper, which will become the liners and fluting medium for corrugated board, or the sheets for paperboard.

Corrugating (for Corrugated Fiberboard): For corrugated board, the flat paper rolls are fed into a corrugator machine. One roll is heated and pressed through large, grooved rollers to create the distinctive wavy (fluted) shape. Adhesive (typically starch-based) is then applied to the tips of these flutes, and flat linerboards are pressed onto both sides, creating the strong, multi-layered corrugated sheet.

Converting: The large sheets of paperboard or corrugated fiberboard are then cut, creased, printed, and folded according to specific packaging designs. This is where the material transforms into boxes, cartons, displays, and other packaging solutions, ready to protect and present products across countless industries.

This foundational understanding of cardboard's composition and creation sets the stage for exploring its myriad advantages and its pivotal role in modern commerce and sustainability.

2.The Unrivaled Advantages of Cardboard Packaging

Cardboard packaging, far from being a mere commodity, stands out as a material with a remarkable suite of advantages that address both practical business needs and growing environmental concerns. Its widespread adoption is a testament to its versatility, cost-effectiveness, and, most notably, its championing role in the drive towards a more sustainable future.

Sustainability Champion: Leading the Green Revolution

In an era where environmental responsibility is paramount, cardboard packaging shines as a beacon of sustainability. Its green credentials are robust and multifaceted, making it a preferred choice for eco-conscious businesses and consumers alike.

Renewability: Unlike fossil-fuel-derived plastics, cardboard is sourced primarily from trees – a renewable resource. Responsible forestry practices, including replanting initiatives, ensure a continuous supply without depleting natural ecosystems. Many cardboard products are certified by organizations like the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC), guaranteeing they come from sustainably managed forests.

Recyclability: This is perhaps cardboard's most celebrated environmental benefit. Cardboard boasts exceptionally high recycling rates compared to many other packaging materials like plastic or glass. Its widespread acceptance in municipal recycling programs makes it easy for consumers to dispose of it responsibly, feeding into a circular economy where old boxes are transformed into new ones. The infrastructure for cardboard recycling is well-established globally, further enhancing its appeal.

Biodegradability & Compostability: Should cardboard packaging escape the recycling stream, its natural composition means it will break down relatively quickly in landfills or compost environments. This natural decomposition process reduces long-term waste accumulation and minimizes environmental impact, especially when free from non-compostable coatings or adhesives.

Reduced Environmental Footprint: The production of cardboard, particularly when utilizing recycled content, generally has a lower carbon footprint compared to many alternative materials. Furthermore, its lightweight nature, especially with advancements in corrugated board technology, contributes to reduced fuel consumption and lower carbon emissions during transportation. This "lightweighting" trend is a continuous effort to optimize material use without compromising strength.

Circular Economy: Cardboard is a poster child for the circular economy. Its ability to be repeatedly recycled back into new packaging creates a closed-loop system, minimizing waste and maximizing resource efficiency. This contrasts sharply with linear "take-make-dispose" models, positioning cardboard as a key enabler of a more sustainable industrial paradigm.

Versatility & Customization: Design Beyond the Box

Beyond its environmental merits, cardboard's inherent flexibility allows for an astonishing degree of customization, meeting diverse product and brand requirements.

Design Flexibility: From intricate folding cartons for high-end cosmetics to robust shipping containers for heavy machinery, cardboard can be engineered into virtually any shape or size. Its ability to be easily cut, creased, folded, and glued facilitates complex structural designs, including internal fitments, display stands, and even creative unboxing experiences. This adaptability allows brands to develop packaging that perfectly encases and presents their products.

Printability: Cardboard offers an excellent surface for high-quality printing, making it a powerful branding and marketing tool. Full-color graphics, intricate designs, QR codes, and vital product information can be directly printed onto the packaging, eliminating the need for additional labels or sleeves. This not only enhances brand visibility and consumer appeal but also streamlines production processes.

Protective Qualities: Despite its paper-based origin, corrugated cardboard, in particular, offers exceptional protective qualities. The fluted structure acts as a natural shock absorber, cushioning contents from impacts during transit. It provides a degree of insulation against temperature fluctuations and, when treated, can offer resistance against moisture, grease, or punctures, ensuring product integrity from warehouse to doorstep.

Cost-Effectiveness: Smart Economics for Business

While initial perceptions might focus solely on material cost, cardboard packaging often proves to be an economical choice when considering the broader supply chain.

Material Cost: Compared to some rigid plastics, glass, or metals, the raw material cost of cardboard is generally competitive, especially given the abundant supply of virgin and recycled fibers.

Transportation Efficiencies: Cardboard's lightweight nature directly translates to lower shipping costs. Furthermore, its ability to be shipped and stored flat before assembly significantly reduces warehousing space requirements and transportation volume, leading to substantial logistical savings.

Production Efficiencies: The speed and automation possible in modern cardboard converting plants contribute to efficient production runs, further driving down unit costs for businesses.

Consumer Appeal: Resonating with Modern Values

Finally, in today's market, packaging is not just about protection; it's about connection. Cardboard packaging resonates strongly with contemporary consumer values.

Eco-Friendly Perception: Consumers increasingly prioritize sustainability. Packaging made from clearly recyclable and renewable materials like cardboard is viewed favorably, enhancing brand perception and fostering loyalty among environmentally conscious shoppers.

Authenticity and Simplicity: There's a growing appreciation for natural, unpretentious materials. Cardboard often conveys a sense of authenticity, simplicity, and transparency, aligning with minimalist trends and a desire for less artificiality.

Unboxing Experience: As discussed later, the tactile and visual qualities of well-designed cardboard packaging contribute significantly to the unboxing experience, particularly in e-commerce, creating a memorable and shareable moment for the consumer.

3.Cardboard Packaging in the E-commerce Era: From Shelf Appeal to Shipping Resilience

The explosive growth of e-commerce in the last two decades, a trend that accelerated dramatically during recent global events, has fundamentally reshaped the packaging industry. No material has been more central to this transformation than cardboard, particularly corrugated fiberboard. The demands of direct-to-consumer shipping, coupled with evolving consumer expectations, have pushed cardboard packaging to new frontiers of design, efficiency, and experience.

Explosive Growth: The Unsung Hero of Online Retail

The direct correlation between the rise of e-commerce and the surging demand for corrugated packaging is undeniable. As more goods are ordered online and shipped individually to homes, the need for robust, protective, and efficient transit packaging has skyrocketed. Cardboard boxes have become the ubiquitous delivery vehicle for everything from electronics and apparel to groceries and furniture, serving as the physical backbone of the digital marketplace. This continuous demand has driven significant investment in cardboard manufacturing capacity and innovation.

Optimized Designs: Tailoring for Direct-to-Consumer Shipping

The transition from traditional retail (where products are typically shipped in bulk to stores) to e-commerce (where individual items are shipped directly to consumers) has necessitated a complete rethinking of packaging design.

Right-Sizing: A critical trend in e-commerce packaging is "right-sizing" or "fit-to-product" packaging. Traditional retail packaging often had extra space for shelf presence or display. For e-commerce, oversized boxes lead to wasted material, increased shipping costs (due to dimensional weight pricing), and a greater environmental footprint. Designers now focus on creating custom-sized cardboard boxes that snugly fit the product, minimizing void fill and maximizing cube efficiency in shipping vehicles.

Minimal Void Fill: Related to right-sizing, the goal is to reduce or eliminate the need for excessive void fill materials like plastic air pillows or polystyrene peanuts. Cardboard's inherent cushioning properties, coupled with clever internal die-cut inserts and clever folding techniques, allow many products to be securely packaged with minimal or even no additional filling, enhancing both sustainability and the unboxing experience.

Reduced Damage in Transit: E-commerce parcels endure a more rigorous journey than palletized shipments to stores. They face multiple sorting centers, transfers, and handling points. Corrugated cardboard, especially double or triple-wall varieties, is engineered to withstand these stresses, providing superior crush resistance, stackability, and impact absorption, thereby minimizing product damage and costly returns.

Ease of Opening: While robust, e-commerce packaging also needs to be user-friendly. Innovations like tear strips, perforated openings, and auto-lock bottom designs make it easier for consumers to open packages without tools, improving convenience and reducing frustration.

The Unboxing Experience: Packaging as a Brand Touchpoint

In the absence of a physical storefront, e-commerce packaging has emerged as a crucial brand touchpoint. The moment a customer receives and opens a package, known as the "unboxing experience," has become a significant factor in customer satisfaction and brand loyalty. Cardboard plays a starring role here:

Brand Storytelling: Cardboard's excellent printability allows brands to extend their identity beyond their website. High-quality graphics, brand colors, custom messages, and even storytelling elements can be printed directly onto the inside or outside of the box, creating a cohesive brand narrative.

Emotional Connection: A well-designed, visually appealing, and easy-to-open cardboard package can evoke positive emotions, making the customer feel valued and excited about their purchase. This can lead to repeat business and organic social media sharing, as consumers often post "unboxing" videos or photos online.

Sustainability as a Statement: For many modern consumers, receiving a product in recyclable and minimalist cardboard packaging reinforces the brand's commitment to sustainability. This aligns with their values and contributes to a positive perception of the company.

Practical Information: Beyond aesthetics, packaging can convey practical information. QR codes printed on the cardboard can link to product instructions, customer support, or even recycling guidelines, enhancing the overall consumer journey.

In essence, cardboard packaging has transitioned from a mere protective shell to an integral part of the e-commerce business model, serving not only as a safeguard for goods but also as a powerful tool for brand building, customer engagement, and sustainable practice in the digital age.

4.Innovations and Future Trends in Cardboard Packaging: Shaping 2025 and Beyond

The world of cardboard packaging is far from static. Driven by evolving consumer demands, technological advancements, and pressing environmental concerns, the industry is continuously innovating. Looking towards 2025 and the years that follow, we can anticipate even more sophisticated and sustainable solutions emerging from the humble paperboard.

Advanced Materials: Pushing the Boundaries of Performance

The core material itself is undergoing significant evolution, aiming to deliver enhanced performance with reduced environmental impact.

Lighter Yet Stronger: Research and development are intensely focused on creating corrugated board that is thinner and lighter but maintains or even improves its protective qualities. This involves optimizing fiber composition, refining the corrugating process, and utilizing advanced adhesives. The goal is to reduce material usage and transport weight even further, leading to lower carbon emissions and material costs. Expect to see more widespread adoption of high-performance fluting and linerboards that defy traditional weight-to-strength ratios.

Moisture and Grease Resistance: Historically, cardboard's Achilles' heel has been its susceptibility to moisture and grease, limiting its use for certain food products or harsh environments. Innovations are addressing this through:

Barrier Coatings: Development of sustainable, often bio-based, coatings that offer excellent moisture, grease, or oxygen barriers without compromising recyclability or compostability. These are replacing traditional plastic or wax laminates, opening new avenues for cardboard in frozen foods, fresh produce, and fast food.

Fiber Treatments: Directly treating the paper fibers during manufacturing to impart water repellency or grease resistance, rather than relying on external coatings.

Bio-based and Recycled Content Maximization: While already strong in recycling, the push continues to maximize the percentage of recycled content in cardboard while maintaining structural integrity. Simultaneously, there's exploration into novel bio-based additives or alternative fibers that could further enhance performance and sustainability.

Smart Packaging: Connecting the Physical and Digital Worlds

The integration of technology into packaging is transforming cardboard from a static container into an interactive medium.

QR Codes & NFC Tags: Already prevalent, these technologies will become even more sophisticated and ubiquitous. Embedded directly into the cardboard design, they offer instant access to a wealth of information: detailed product specifications, expiry dates, recycling instructions, brand storytelling content, augmented reality (AR) experiences, customer service, or even direct re-ordering links. This enhances transparency and consumer engagement.

Sensors and Indicators: For sensitive products like fresh produce, pharmaceuticals, or high-value electronics, cardboard packaging may increasingly integrate subtle sensors. These could monitor temperature excursions, humidity levels, or impact events during transit, providing real-time data to ensure product integrity and reduce waste. Imagine a produce box that changes color if the fruit inside has overheated.

Anti-Counterfeiting Measures: Advanced printing techniques and integrated digital identifiers in cardboard packaging can provide robust anti-counterfeiting solutions, protecting brands and consumers from fraudulent products.

Automation and AI in Production: The Factory of the Future

The manufacturing and converting of cardboard are benefiting significantly from Industry 4.0 advancements.

Enhanced Automation: From automated warehousing and material handling to robotic assembly lines and advanced cutting technologies, automation is increasing efficiency, reducing labor costs, and improving precision in cardboard production.

Artificial Intelligence (AI) for Optimization: AI is being leveraged for predictive maintenance of machinery, optimizing production schedules, minimizing waste from material off-cuts, and even predicting packaging needs based on sales forecasts, leading to leaner and more responsive supply chains.

Digital Printing: Customization on Demand

Traditional printing methods for packaging often require large print runs to be cost-effective. Digital printing on cardboard is changing this paradigm.

High-Quality, On-Demand Customization: Digital printing allows for short runs, variable data printing (where each box can be unique), and rapid turnaround times. This is perfect for personalized packaging, seasonal promotions, limited editions, or tailoring messages to specific geographic regions without incurring high setup costs.

Prototyping and Speed to Market: Brands can quickly test new packaging designs or marketing messages with digital printing, accelerating the time it takes to bring new products to market.

Reusable and Refillable Systems: The Circularity Revolution

While often associated with durable materials, cardboard has a role to play in supporting the broader shift towards reusable and refillable consumption models.

Integration into Returnable Loops: Cardboard could be used as a lightweight, single-trip component within a larger, multi-trip container system, or as part of a customer-facing return kit for refill programs.

Subscription Box Models: Cardboard remains the go-to for subscription boxes, and innovations here focus on making these boxes more durable for multiple uses by the consumer (e.g., for storage) or easier to return for a refill.

Policy and Regulation: Driving Sustainable Choices

Legislation is playing an increasingly critical role in shaping the future of cardboard packaging.

Extended Producer Responsibility (EPR) Laws: More governments are implementing or strengthening EPR laws, which hold producers responsible for the entire lifecycle of their packaging, including collection and recycling. This incentivizes companies to design packaging that is easily recyclable and made from sustainable materials like cardboard.

Plastic Reduction Targets: Global and national targets for reducing plastic waste are directly driving brands to switch from plastic to paper-based alternatives, significantly boosting the demand for innovative cardboard solutions.

Mandatory Recycled Content: Some regulations may begin to mandate a minimum percentage of recycled content in packaging, further cementing cardboard's sustainable credentials.

5.Challenges and Considerations: Navigating the Complexities of Cardboard Packaging

While cardboard packaging offers significant benefits and is continuously evolving, it's not without its inherent challenges and important considerations that impact its performance, cost, and overall sustainability. Addressing these aspects is key to maximizing its potential and ensuring its long-term viability.

Weather Resistance: Battling the Elements

The primary vulnerability of cardboard packaging stems from its paper-based composition: its susceptibility to moisture.

Water Absorption: Unprotected cardboard readily absorbs water, leading to a rapid loss of structural integrity. This can cause boxes to weaken, collapse, or damage the products inside if exposed to rain, high humidity, or even spills during transit or storage.

Mitigation Efforts & Limitations: While innovations like water-resistant coatings, moisture-resistant glues, and specialized wax treatments exist, these often come with trade-offs. Traditional wax coatings, for instance, can render cardboard unrecyclable, necessitating costly separation processes or diverting it to landfill. The ongoing challenge is to develop effective, truly recyclable, and compostable barrier solutions that can withstand varying environmental conditions without compromising the material's end-of-life options.

Cost Fluctuations: A Volatile Market

The economics of cardboard packaging can be influenced by external market forces, leading to price volatility.

Raw Material Prices: The cost of virgin wood pulp and recycled paper fiber, the primary raw materials for cardboard, can fluctuate significantly due to factors like timber harvests, energy costs, global demand, and the availability of recovered paper. These fluctuations directly impact the production cost of cardboard and, consequently, the price for end-users.

Supply Chain Disruptions: Events like natural disasters, geopolitical tensions, or global economic shifts (as seen in recent years) can disrupt supply chains for pulp, chemicals, or even transportation, leading to sudden price increases or material shortages. Businesses relying heavily on cardboard packaging must often navigate these unpredictable market dynamics.

Waste Management Infrastructure: The Recycling Imperative

While cardboard is highly recyclable, its true sustainability potential relies heavily on robust and efficient waste management systems.

Collection and Sorting: The effectiveness of cardboard recycling depends on widespread consumer participation in proper sorting and the availability of accessible collection points (curbside recycling, drop-off centers). Contamination (e.g., with food waste, plastic liners, or excessive tape) can significantly degrade the quality of recycled fiber and increase processing costs.

Processing Capacity: Even with good collection, sufficient processing capacity (paper mills equipped to de-ink and repulp cardboard) is essential to turn collected material back into usable fiber. Investment in this infrastructure is crucial, especially as global demand for recycled content grows.

Global Disparities: While many developed nations have strong cardboard recycling programs, infrastructure varies widely across different regions and countries, posing a challenge for international brands aiming for consistent sustainability practices worldwide.

Consumer Behavior: The Human Element in the Loop

The success of cardboard's sustainable lifecycle ultimately depends on how consumers interact with it post-use.

Awareness and Education: Not all consumers understand the differences between various types of cardboard or the proper way to dispose of them (e.g., removing non-cardboard elements like plastic windows or packing peanuts). Clear, consistent labeling and public education campaigns are vital to ensure high-quality recycling streams.

Overcoming Contamination: Food residue, grease, or liquids can contaminate cardboard, making it unsuitable for recycling. Educating consumers on when cardboard is too soiled to be recycled (e.g., greasy pizza boxes in some regions) is an ongoing effort.

Reusability vs. Recycling: While recycling is excellent, the hierarchy of waste management places "reduce" and "reuse" above "recycle." Encouraging consumers to reuse cardboard boxes (e.g., for storage, moving, or even creative projects) before recycling can further extend the material's life cycle, although this often requires a conscious effort from the consumer.

By acknowledging these challenges, the cardboard packaging industry can continue to innovate, develop more resilient and truly circular solutions, and collaborate with stakeholders across the supply chain to overcome barriers and solidify its position as a leading sustainable packaging material.

6.Case Studies & Examples: Cardboard Packaging in Action

To truly illustrate the impact and innovation within cardboard packaging, examining how real-world brands are utilizing this material can be incredibly insightful. These examples demonstrate not only the practical applications but also the strategic advantages – from sustainability wins to enhanced brand experiences – that cardboard offers.

The E-commerce Unboxing Revolution

Challenge: How to create a memorable brand experience and protect delicate products during direct-to-consumer shipping, while minimizing environmental impact.

Cardboard Solution: This brand implemented custom-designed corrugated boxes that are precisely sized for their products, eliminating the need for excessive void fill. They invested in high-quality digital printing on the inside of the box, featuring vibrant graphics, a personalized message, and clear recycling instructions. The box design often includes clever internal fitments made from the same corrugated material, securely cradling the product without plastic inserts.

Impact: Customers frequently share their "unboxing" experiences on social media, praising both the product and the thoughtful, sustainable packaging. This strategy has significantly boosted brand loyalty, reduced shipping damages, and reinforced the brand's commitment to sustainability, directly linking a premium unboxing experience with eco-friendly choices.

Sustainable Food Packaging

Challenge: How to package food products that require a degree of moisture or grease resistance, maintain freshness, and be fully recyclable or compostable, moving away from traditional plastic trays or coated cartons that end up in landfill.

Cardboard Solution: This company adopted innovative paperboard solutions featuring advanced bio-based or water-soluble barrier coatings. For ready meals, they might use oven-safe, grease-resistant paperboard trays that can go directly from freezer to oven and then be recycled with regular paper. For produce, they might utilize breathable, naturally moisture-resistant corrugated punnets that replace plastic clamshells.

Impact: This move resonated strongly with consumers seeking convenient, yet environmentally responsible food options. It allowed the brand to prominently feature their sustainability efforts on their packaging, differentiating them in a competitive market and contributing to a significant reduction in plastic waste from their operations.

Industrial Packaging & Supply Chain Efficiency

Challenge: How to securely ship heavy, complex, or sensitive industrial components without relying on expensive, heavy wooden crates or bulky, non-recyclable materials, while optimizing warehouse space and logistics.

Cardboard Solution: This manufacturer transitioned to engineered triple-wall corrugated containers, often custom-designed with intricate internal cardboard fitments and dunnage. These solutions are developed through extensive testing to withstand significant weight, stacking pressure, and transit vibrations. The flat-pack nature of the corrugated material before assembly allowed for massive savings in storage space and inbound shipping.

Impact: The switch led to substantial reductions in freight costs due to the lighter weight of the packaging. Damage rates decreased due to superior cushioning. Furthermore, the recyclability of the packaging aligned with their corporate sustainability goals, and the ease of disposal for their industrial clients was an added benefit compared to managing wooden crate waste.

Direct Mail & Marketing Innovation

Challenge: How to cut through digital noise and create a tangible, engaging marketing piece that feels personal and encourages action, while also being environmentally responsible.

Cardboard Solution: This organization utilized high-quality paperboard for uniquely shaped direct mail pieces or subscription box components. They leveraged digital printing for personalized messages and vibrant graphics, creating a premium feel. The tactile nature and structural possibilities of the cardboard allowed them to incorporate interactive elements like pop-ups or secret compartments.

Impact: Their campaigns saw significantly higher engagement rates compared to generic mailers or purely digital outreach. The memorable, tangible nature of the cardboard piece, combined with its recyclable attribute, contributed to a positive brand image and stronger emotional connection with their audience.

Conclusion:

Cardboard packaging is more than just a box; it's a dynamic, adaptable, and increasingly intelligent solution that balances commercial needs with environmental imperatives. As global consciousness around sustainability grows and e-commerce continues its expansion, cardboard is not merely keeping pace but leading the way, firmly establishing itself as an unsung hero and a cornerstone of a more sustainable and efficient future.

English

English Español

Español